As robot installations continue to grow, more designers are specifying thin section bearings to save space and weight. Less weight lets robots maximize payload and reduce inertia, improving response and optimizing power requirements. Compact components let them meet stringent space requirements. Kaydon Reali-Slim thin section bearings deliver both advantages: a Reali-Slim KA020CP0, for example, reduces weight by 83 percent and space by 85 percent compared to a standard 6010 bearing. Reali-Slim bearings have a cross-section that does not increase with the bore diameter, yet they provide precision with plenty of dynamic capacity. They are available in radial, angular and four-point configurations. The latter, which accepts combined radial, thrust and overturning moment loads, can replace two angular contact bearings to simplify overall robot design.

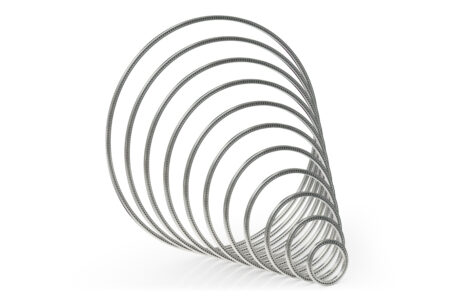

Ultra-Slim thin section bearing from Kaydon

Duplex mountings

For the best combination of low torque and high stiffness, Kaydon offers duplex pairs, preloaded to eliminate the need for shimming. Also offered are super duplex bearings with a single common race (either outer or inner) and two ball paths for applications requiring greater stiffness. Kaydon cartridge bearings go a step further, with a single inner race and single outer race for optimal torque performance.

Meeting the challenges of robotics

Kaydon has been developing successful engineering solutions for over 75 years. A leading global producer of high-precision bearings and high-level bearing assemblies, Kaydon offers comprehensive engineering and technical support that includes expertise in a wide range of robotic applications in industries such as industrial (painting, welding, handling), medical (robotic surgery, artificial limbs, personal robots, exoskeletons), semiconductor (wafer transfer, pick-and-place), Oil&Gas (iron roughnecks); aerospace and defense (UAVs Unmanned Aerial Vehicles, UGVs Unmanned Ground Vehicles, Mars Rovers).

Application example

The Robocut laser cutter from Robot-Technology GmbH of Germany is used mainly to cut plastic cladding parts in automotive manufacturing. However, it can also cut PP, PE, ABS-PC, Plexiglas, TPO films, a variety of textiles, and even steel panels up to 3 mm thick. With very limited installation space for the bearing assembly, the Robocut needed bearings with a very thin cross-section but a relatively large diameter. The bearings also had to be very rugged, since laser cutting creates dust and gases that can interfere with smooth bearing rotation. Reali-Slim bearings met the challenge.

Over 425 sizes and configurations

Kaydon’s thin section bearings, a concept introduced by Kaydon in the 1950s, are available from stock in over 425 sizes and configurations, standard and custom. Popular options for robotic applications include stainless steel and special lubrication for vacuum conditions. Full details are available at www.kaydonbearings.com, including an interactive bearing selector, and downloadable Reali-Design software. Kaydon is also a top manufacturer of slewing ring bearings, which are commonly used in waist positions. These deliver excellent rotational accuracy, load capacity and long life, with integral configurations (mounting bolt holes, seals, gearing, etc.) that can lead to big savings in materials and assembly.

DOWNLOAD THE BROCHURE:

https://www.kaydonbearings.com/downloads/Kaydon_Robotics_Automation_Broch_R1.pdf