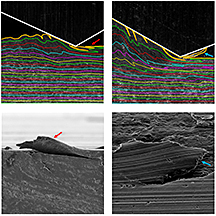

Researchers at Purdue University have discovered a previously unknown mechanism for wear in metals: a swirling, fluid-like microscopic behavior in a solid piece of metal sliding over another.  Wear is a major cause of failure in engineering applications however, the researchers findings have implications beyond wear itself, extending to manufacturing and materials processing. Using high-resolution imaging of sliding contacts in metals, they have demonstrated a new way by which wear particles and surface defects can form: previously they revealed the formation of bumps, folds and vortex-like features on sliding metal surfaces. This research work is a collaboration of researchers from Purdue, the Indian Institute of Science in Bangalore, India, and M4 Sciences, a company in West Lafayette, Indiana. The findings could be used to improve the durability of metal parts in numerous applications.

Wear is a major cause of failure in engineering applications however, the researchers findings have implications beyond wear itself, extending to manufacturing and materials processing. Using high-resolution imaging of sliding contacts in metals, they have demonstrated a new way by which wear particles and surface defects can form: previously they revealed the formation of bumps, folds and vortex-like features on sliding metal surfaces. This research work is a collaboration of researchers from Purdue, the Indian Institute of Science in Bangalore, India, and M4 Sciences, a company in West Lafayette, Indiana. The findings could be used to improve the durability of metal parts in numerous applications.

Learn more: http://www.purdue.edu/newsroom/releases/2014/Q3/discovery-is-key-to-metal-wear-in-sliding-parts.html