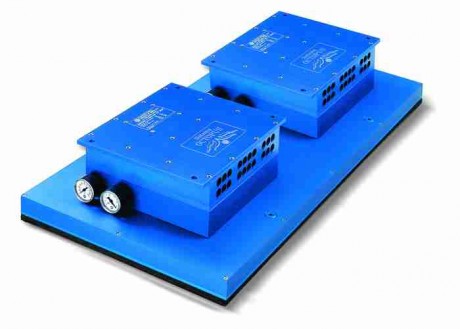

Vuototecnica designed and produced Octopus to respond to the increasingly frequent demand for operational flexibility of vacuum gripping systems. It is a range for all needs, with a wide choice of accessories and components according to use. Octopus guarantees the grip of objects of any shape and nature, in safety, without continuous changes of position of the suction cups and it is effective in all conditions, even when the surface of the objects takes up only 5% of the suction plate. The Octopus systems are composed of:

- a vacuum generator powered by compressed air;

- an anodized aluminum box, open on one side, with a built in stainless steel micro fine mesh filter, to protect the generator, which can be easily inspected;

- a suction plate to close the box, in anodized aluminum, and coated with a special perforated foam rubber, able to adapt perfectly to any surface (smooth, rough or irregular).

Lightweight

The market today requires extreme lightness. Octopus is also available in the form of gripping bars in polyzene, a plastic material that reduces the overall weight by about 40% compared to traditional aluminum bars. The bars in polyzene still retain all the strengths of traditional aluminum bars and they are based on the same principle of operation.

Flexibility

Octopus vacuum gripping bars can operate vertically, horizontally, inclined and upside down to the gripping plan of the objects. You can choose the suction plates depending on the surfaces of the objects to manipulate. It is therefore possible to opt for gripping plans with gaskets spongy, perfect for gripping objects with very irregular surfaces or with suction cups of different nature and shape. Both types of suction plates (spongy rubber and suction cups) can be equipped with shut-off valves to concentrate the suction only and exclusively in the area which is in contact with the product to manipulate. Octopus is perfect in dusty environments, too. There are in fact suction plates with calibrated and self-cleaning micropores in the Octopus range.

Application fields

Companies need tools that are able to support the continuous cycles of work of robots and that avoid wastage of time and money. Octopus system is a response to the need for palletizing and de-palletizing in several industries. Octopus is therefore ideal to stack and unstack cartons, sacks and boxes ensuring even the grip of carton, and wooden pallets, interlayers.