Link International is an all-round partner in the world of gearboxes

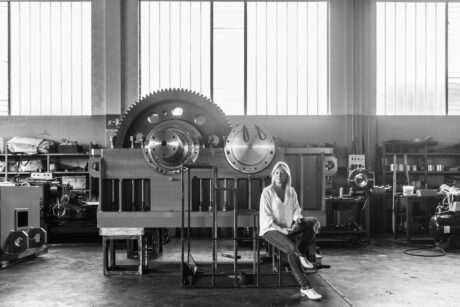

Link International is one of the few companies in Italy able to offer a complete service concerning special gearboxes, for both the new engineering and revamping. The founder, Elisa Brescianini, and all of her collaborators come from the engineering environment and rely on previous expertise in the sector: from the provenience companies, they have inherited design know-how and the manufacturing secrets of special gearboxes, activity that today is one of the primary ones performed by Link International. In addition to that, however, Link also takes care of overhaul, maintenance and revamping of multi-brand gearboxes, both standard and special. This variety of offer is this company’s peculiarity and distinguishes it from competitors: not many companies carry out activities of revamping and design of special parts because they are very challenging tasks and they do not operate on mass-production numbers.

The products by Link International are very customized. Concerning the engineering of tailored components, it takes place in strict contact with customers: «We design the part together and we dedicate to this phase – the most delicate – all the necessary time, even when it takes weeks. This is a distinguishing trait of Link International: although a project may be complicated and challenging, the result demanded by the customer remains at the core of our focus. The finished product that leaves our workshops is just the last stage of a wok started some months ago with the customer» Brescianini explains.

Special gearboxes

Among the “special” demands that Link International is called to satisfy, many are requests of upgrading of gearboxes become obsolete, which must be ruled or enhanced. In that phase, the original gearbox is no longer suitable and Link International, maintaining the same condition, implements it again with a new shape and new interfaces, to adapt it to the plant. Other demands received by the company are the boosting of power or of performances, with the introduction of smaller but more efficient motors. However, they are niche works needing peculiar know-how indeed.

New or overhauled gearbox?

In the last years the technology of gearboxes has made great strides in terms of innovations: new materials and new treatments, toothing that make gearboxes more efficient and less cumbersome, with rise of powers but decrease of the materials used are the most evident changes. The demand for a new gearbox may derive also from the will of introducing more innovative technologies, to make the machine more efficient on the whole. In fact, also the gearbox can share in notably increasing machines’ efficiency and this has aided some of Link customers in benefitting from aids for Industry 4.0 or for the energy efficiency. Energy savings are tangible by equipping also old machines with a modern gearbox.

Why carrying out the revamping?

The revamping of an existing gearbox implies acting on the original component, by restoring the original constituting operation conditions through the replacement of worn-out components with new components. Link International is specialized in the multi-brand service on whatever type of standard and special gearbox, intervening by the customer’s plant, too. The revamping is often dictated by economic reasons because it costs about 60% of the cost of a new gearbox and recovers a piece covered by a two-year warranty and featuring a functionality that is comparable to the new. Otherwise, a question that might be summarized in the following saying comes into play: “never change a winning team”: for the decision-maker, choosing of revamping a gearbox that has always worked well on a certain machine is simpler than manufacturing one from scratch.

The market of Link International

Link international deals with all gearboxes, from the smallest ones to those weighing some tons. Most of them have intermediate sizes, from 1000 to 4500 kg. The materials used are traditionally materials from hardening, tempering and related treatments. The company’s reference markets range from the users of steel working plants to oil&gas, papermills, the rubber and plastic industry, the chemical, pharmaceutical and food sectors.