Oriental Motor, Japanese company operating in over forty Countries in the world and global leader in the manufacturing of electric motors, high-precision linear and rotary actuators with relative drivers suiting numerous application sectors, has released the new series of BLV-R motors: they are light motors and drivers for battery applications.

It is a range of products that represents the evolution of the previous BLV series and that, like this one, is composed by a DC brushless system for DC power supply, formed by a gearmotor with piloting driver, improved to follow the process of progressive technological upgrading that in recent years has concerned the broad range of products offered to the market, which includes stepper motors and servomotors, as well as DC brushless motors, asynchronous motors, actuators and fans.

Modular automation

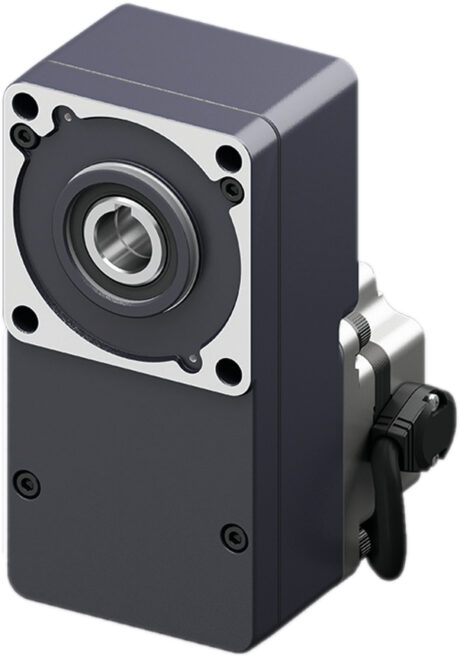

The motors of the BLV-R series are proposed in different versions: with parallel-axis gears, with hollow-shaft flat gears and smooth-shaft motors, without gear and with electromagnetic brake. In the case of hollow shaft gears, the engineering grants a notable reduction of space and overall dimensions, permitting a direct assembling, without connection elements like joints, to users. Precisely compactness is one of the added values of the new product series, as underlines Silvio Nebbiati, Sales Manager of the Italian branch of Oriental Motor.

«It is – he says – an advanced product just starting from design, to reach, obviously, performances and management. Furthermore, offering the possibility of choosing among four motor sizes in the range, we can intercept the requirements of a broad series of applications that need to power the driver by means of battery, starting from automated-drive vehicles, like forklift trucks equipping the industrial manufacturing lines and ecologic brushing machines».

The ameliorative effort made by the corporate research sector is well visible in the finished product. «In the last years – Nebbiati adds – the company has worked to improve systematically its product portfolio, following and often anticipating market trends through a constant attention paid to the technological evolution, which allows us to match fully the modular automation concept, applied by the company also in the packages composed by stepper motors and drivers, in closed-loop versions. This philosophy leads to the offer of solutions that, to work, must not be necessarily connected to the electric network and then become strongly attractive if applied to self-propelled equipment. Other bearing concept for our strategies is linked with flexibility, which induces to give up the idea of fixed production to study a series of products that stand out for lightness, small footprint and, precisely, flexibility, which allows them to perform different functions according to their configuration».

Improved performances

Due to the various functions with which it is provided, the BLV-R series can therefore suit different applications, such as the torque limitation, useful to prevent blocks of the overloaded motor, as well as the function that permits the load to be maintained with the motor stopped, even without the electromagnetic brake. Novelties also in the enhanced offer of motor sizes that offer even more options, since, besides the nominal powers of 200 and 400 watts that characterized the previous BLV series, today also 60-watt sizes exist (also in the version with CS new-concept gear featuring centred shaft) and 100-watt ones. Therefore, the new motors allow transporting even heavier inertia loads and products than in previous versions, contributing in the design of more compact high-power systems. A practical example: two 400-watt motors with flat gears can move an automated-drive vehicle with a load of 500 kg at a speed of 0.7 m/s.

Drives are ideal also for the operation of mixers that use liquids with different viscosity at constant speed, as well as conveyor belts or in general in low-noise applications. Brushless motors permit start and stop of fluids in the whole speed range, from 1 to 4000 rpm. In that way, for instance, an AGV can avoid obstacles or other vehicles without affecting the load, with a stop position that can be defined with millimetric precision. Concerning the consumption issue, the optimization achieved by batteries’ performances allows equipment to travel longer distances and to work for a longer time, with Mexe 02 support software that, besides monitoring the charge situation in real time, allows a complete control of information data and flows.

Reduced wirings

Speaking of compactness, it is finally worth highlighting the small sizes of the driver, whose overall dimensions have been reduced by 80%: 65x75x29 mm, for 120 grams of weight only. Compatible with CANopen and Modbus RTU interfaces, it offers the possibility of sending simultaneously the position data of the various axes, significantly shortening the transmission delay. With this solution, users have undoubted advantages also in terms of connections versus the previous version. In this case, in fact, the presence of wires is minimized and a single application wire is sufficient to make the machine operational and efficient.