Boost your projects. This is the claim of Conforti Oleodinamica, Italian company with an approximate turnover of 5 million Euros and a yearly production of 15,000 hydraulic cylinders for high performance industrial applications. The CEO Matteo Conforti Andreoni talks about that.

Let us start from the current 2023. How is the market going and, in your opinion, what are the trends of the hydraulic market today?

We have a particularly positive year behind for our company, which has witnessed the achievement of significant rises of our manufacturing volumes, unfortunately joined also by strong rises of materials’ and energy’s costs, which have affected and will influence the price trend. The signals that we seize from our reference markets make us optimistic for 2023, despite the great uncertainties that have characterized international scenarios for some years now.

In a context of such a high variability, customers will be able to award the companies that will prove to be more reliable, closer to them and more able to grant service continuity and stability. Conforti has succeeded in overcoming these turbulent years always at customers’ side, due to a team of people who every day work to play this game together and to be considered a partner on which relying.

When was Conforti Oleodinamica born and how does it evolve?

1972, a year worth reminding. Bill Gates and Paul Allen establish that company that shortly after became Microsoft, a sergeant of the Japanese army is found in a forest of Guam island, convinced that the second world war had not ended, the moon Apollo 17 mission ends, the last with human crew, FIAT shows the new Fiat 126 to the public and in Monza Conforti Oleodinamica starts designing and manufacturing its hydraulic cylinders in Monza. In the course of the Nineties, the company specializes in cylinders complying with ISO standards, more and more refining its offer towards the direction of high-quality and reliability products, with timely deliveries and prompt response times.

What customers do you address and what are the applicative fields of your products?

Conforti hydraulic cylinders are used in all industrial application fields that require high reliability, precise motion and big forces at stake. Each design of our customers – either in the automotive, iron and steel, packaging, pharmaceutical, food and hydroelectric sector – is an important project for us, where to do the best to feel partners of our customers and not only mere suppliers, because we are aware that together we can give an edge to projects that are also proudly ours.

Quality and reliability have led the company to be a benchmark for the international market. The production is exclusively made in Italy, in Monza headquarters, but a network of authorized distributors allows reaching customers worldwide.

What is the product range in your catalogue and what are the “top products”?

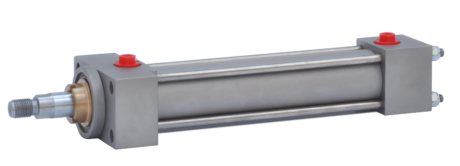

Our outstanding product is certainly the ISO 6020/2 hydraulic cylinder with tie rods, also in the version with magnetic position sensors. This product type is designed in extremely modular way and it allows achieving the whole very broad range of possible configurations starting from standard components, which we regularly stock up in the large warehouse, always supplied with any item.  Moreover, we also offer our customers compact aluminium and steel hydraulic cylinders, ISO6022 cylinders for heavy duty applications and rotary actuators, also in the version with magnetic position sensors. We have witnessed for years on the market the boost towards the cylinder integration with control systems, also with our ISO 6020/2 and ISO 6022 servo-cylinders, provided with position transducer, as well as with the whole series of applicative solutions for integration of proximity and pressure sensors inside the cylinder body.

Moreover, we also offer our customers compact aluminium and steel hydraulic cylinders, ISO6022 cylinders for heavy duty applications and rotary actuators, also in the version with magnetic position sensors. We have witnessed for years on the market the boost towards the cylinder integration with control systems, also with our ISO 6020/2 and ISO 6022 servo-cylinders, provided with position transducer, as well as with the whole series of applicative solutions for integration of proximity and pressure sensors inside the cylinder body.

How do you operate in terms of research and development and what are the investments in recent years?

The future of an excellent product is granted by the service connected with it. Conforti’s constant research in satisfying the unceasing demands has led and induces every day to the commitment to the research of innovative technical and information solutions, to make our customers’ projects more profitable. Along the years and with constant investments, we have taken care of the implementation and integration of the information systems that support customers on line, our sales offices and the manufacturing and testing machines. Industry 4.0 has been a reality for us for several years and our customers know.

The capability of offering an excellent service to customers in pre-sale phase and of being prompt and reliable in manufacturing times becomes more and more decisive. Our average delivery terms are 10 days, but our customers with particular urgencies can always rely on our fast 48-hour service, particularly appreciated. Our website, recently updated, is equipped with advanced tools of product configuration and guided design starting from the functional requirements of the application, besides an e-commerce area able to quote and to validate automatically also a broad range of customizations of the base product.

Of what technologies and of what innovative solutions are you particularly proud?

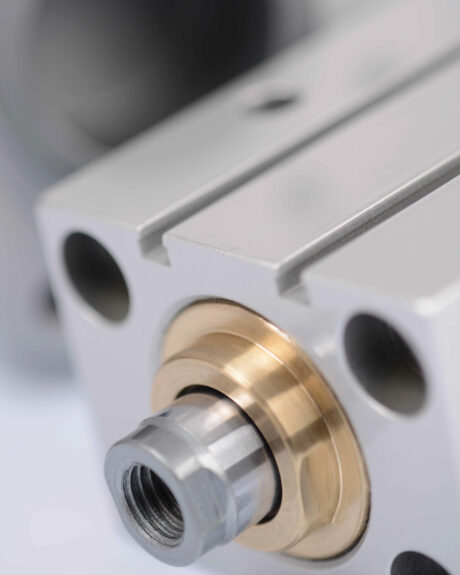

Conforti Oleodinamica works at all phases of the manufacturing cycle, from the initial design to testing. The materials used are of excellent quality and the machining of all components is carried out inside the company. With this system, we succeed in intercepting and assessing eventual defects or potential criticalities that might emerge, preventively analysing them and intervening to avoid the onset of non-conformities.

Due to the expertise gained in these years, we have obtained a consolidated product that is constantly upgraded and improved, just thanks to the possibility of supervising all machining phases. Each finished cylinder is fully tested according to the ISO 10100 regulation before its delivery, and it is supplied with certificate where are highlighted all the data registered by the test bench. The technical solutions adopted, progressively improved along the years, and the solutions implemented grant a reliable product in time. All machining phases are traced to be able to trace back, if some problems should occur, the starting material, machining times and the operator who fulfilled that specific order. Finally, electronic parts and sensors are purchased from selected companies and afterwards integrated and tested by Conforti Oleodinamica inside the various products.

Let us speak of sustainability…

Conforti pays particular attention to the protection of the environment and of the community where we are integrated. For over 10 years, we have exploited the energy produced by our photovoltaic plant and more recently we have started some specific initiatives, like the replacement of steels containing lead with others that are free but that can grant the same performance characteristics, or the use of recyclable materials for product packages.

An example of history

Concerning the question of indicating a product that can constitute an example to explain concretely what Conforti Oleodinamica can offer to customers, the CEO Matteo Conforti Andreoni explains: «Our ISO6020/2 cylinders are available with nickel plating of outer surfaces. With this treatment, the cylinder can be for instance applied to machines operating in particular sectors, like the pharmaceutical or the food one, or in aggressive and corrosive environments, and it is an excellent replacement of the fully stainless-steel cylinder, which is often very expensive and hardly available.

Maintaining all the qualitative features of Conforti cylinder with tie rods, the product is treated with a chemical nickel-plating process. The surface is coated by a determinate specific Nickel layer that, as a result, assures a product with very high resistance to corrosion (1200 hours in saline mist -rating10). The nickel-plating process that Conforti has studied in collaboration with an Italian company specialized in this kind of treatments provides for the total absence of heavy metals and ammonia and a very low environmental impact, always very important aspect that Conforti Oleodinamica has pursued for many years.»