Trucks, cars and motorcycles are energy-guzzlers: over 60 percent of the energy generated in their engines by fuel is lost through the exhaust gas and the coolant. The biggest part of this simply slips off into the environment as heat. Beneath engine hoods, gasoline, diesel and electricity are wasted and unnecessarily pumped into the air through the exhaust system as CO2. The “new drive systems” project group at Fraunhofer Institute for Chemical Technology ICT in Karlsruhe, is probing the causes for this kind of waste. Together with other researchers, it is developing efficient drive concepts for vehicles. In the laboratory, they have already succeeded in increasing the degree of efficiency of car engines by five percent, and up to ten percent for commercial vehicle powertrains.

The scientists have new test facilities available since this summer. “At the Karlsruhe location, we were able to map the entire process of powertrain development: from design to simulation and to testing,“ says Kollmeier. The researcher’s goal is to optimize the technologies of the drivetrain being utilized, so that the fuel savings is optimal. For this purpose, you must know how the individual components interact with each other in reality. “With the new testing options, we have come one huge step closer to this goal. Through this effort, we have the opportunity to test the drivetrain as a whole, and validate our simulations,“ says Kollmeier.

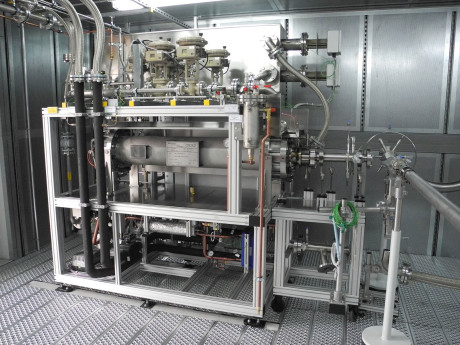

The linchpin of this new test infrastructure is an engine and hot gas test stand. There, researchers can analyze engines and their components both mechanically and thermodynamically. A computer controls the systems and simulates realistic application scenarios. For example, the computer can additionally switch on virtual hybrid drives (like electric motors) or systems that use waste heat. The scientists analyze how the vehicle drive acts with regard to fuel consumption and CO2 emissions. For this purpose, Kollmeier’s team simulated vehicle in terms of type, route, or driver methods accordingly. Once sufficient data are gathered, the researchers build prototypes and then gradually substitute the simulation models through real components in the test facility. Step by step, they are thus arriving at the optimal powertrain. In the process, lightweight materials become increasingly important.

If it is about making car engines more efficient, then the term “downsizing” comes into play. Generally speaking, it is minimizing the displacement of the engine, without reducing its performance capacity. Through the diminished friction resistance and the improved thermodynamic process, we can reduce fuel consumption and CO2 emissions. As a rule, turbo-chargers are used in downsizing concepts, which are integrated into the suction and exhaust tract. These screw-shaped components – about 15 centimeters in cars – suck up air and push it into the internal combustion engine. Thus, more fresh air is conducted to the engine, which allows for a greater quantity of fuel to be consumed. Due to the higher cylinder pressure that this reaches, higher engine power is also achieved for the same engine displacement. The turbocharger is driven by the exhaust gas of the vehicle. At the hot gas test facility, the scientists are testing their turbo-chargers. At this facility, a certain exhaust gas mass power is generated by a natural gas burner which corresponds to that of an internal combustion engine. The burner can be set very precisely, in order to analyze how the most miniscule changes to peripheral conditions affect the turbo chargers.