Given that internal combustion (IC) engines used to power automobiles are intended to drive wheels, it might seem obvious that engines which produces rotary rather than reciprocating motion in the first place would be preferable.  But the reality is that piston engines have long established an overwhelming predominance in the worldwide automotive industry. According to Phil Gott, analyst with IHS Automotive, sound reasons for this exist in the U.S. He points out that though rotary engines are capable of high power densities and smooth operation, they have also generally proved much less fuel efficient and also more prone to generate high levels of hydrocarbon emissions than reciprocating counterparts. But the rotary engine concept has never gone away. Moreover, and perhaps ironically, at a time when fuel efficiency and environmental friendliness are regarded as priorities there is renewed interest in rotary technology as a means of achieving those goals.

But the reality is that piston engines have long established an overwhelming predominance in the worldwide automotive industry. According to Phil Gott, analyst with IHS Automotive, sound reasons for this exist in the U.S. He points out that though rotary engines are capable of high power densities and smooth operation, they have also generally proved much less fuel efficient and also more prone to generate high levels of hydrocarbon emissions than reciprocating counterparts. But the rotary engine concept has never gone away. Moreover, and perhaps ironically, at a time when fuel efficiency and environmental friendliness are regarded as priorities there is renewed interest in rotary technology as a means of achieving those goals.

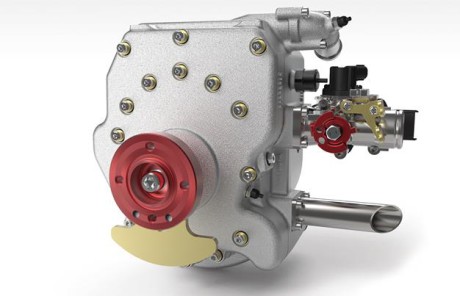

“A petrol engine with the efficiency of a diesel counterpart” is the promise held out for a rotary engine being developed by Libralato based in Manchester in the UK. The words are those of Dan Aris, managing director, who says that though the idea for the engine originated with Italian engineer Dr. Ruggero Libralato just over 25 years ago, the first proof of concept tests took place as recently as 2011. As such, says Aris, it is still “fairly early days” for the engine, although testing has already taken place on a testbed at a UK university.

Aris says the engine has a number of a highly distinctive features. The thermodynamic cycle, for instance, is “completely new” and “all of the engine phases take place in parallel in each rotation of the engine.” What this means is that the engine “has a power phase in every rotation” and therefore “has twice the power density of a typical reciprocating engine.”

Aris says that a key enabling factor is that the engine has “asymmetrical expansion and compression volumes” which means the expansion volume is greater than the compression volume. As a result, more work can be extracted from the combustion of the fuel-air mixture meaning that the concept could be described, in his words, as a “rotary Atkinson Cycle engine.”

Learn more: http://insights.globalspec.com/article/280/round-and-round-we-go-rotary-engines-for-automotive-applications