F.lli Giacomello is a company specialized in highly performing level gauges, tailor-made according to customers’ specifications. Face to face with the general manager Daniele Giacomello.

The application ambits of levels are more and more numerous and the work conditions increasingly heavy-duty, to the extent of demanding for very advanced products designed according to ever-changing requirements. To satisfy all demands, F.lli Giacomello, historical Italian enterprise headquartered at Rho (MI), has organized in time the suitable structure for designing tailored solutions for each customer, in compliance with the peculiar specifications of each job order. Relying on thirty-year specialization, the company can design and produce level indicators of numerous typologies, in short times and provided with all main certifications today required on the market. «F.lli Giacomello – explains the general manager Daniele Giacomello – stemmed over thirty years ago from my father’s idea as he set it up as small family-owned company together with his brother. At the beginning, the activity consisted in small subcontracting productions but afterwards they started the manufacturing of our level gauges, for which we have registered several patents. Hand in hand with the business development, they enlarged the structure and moved it to new premises, with an ever-growing team able to suit the new requirements». After the father’s death, at that time owner of the company, Daniele Giacomello takes over the family business, after years of apprenticeship that have allowed him to know products and manufacturing processes in their slightest details. «My long apprenticeship was hard but very educational for me – the general manager comments-, as it allowed me to gain long experience and to know in-depth products and sector».

Fully customized products

Due to this know-how gained on the field in the long term, today F.lli Giacomello can implement each product upon design, in-house assembling all parts. This kind of activity enables the enterprise to develop constantly new solutions, in conformity with the latest sector requirements and at the same time maintaining a direct strict contact with each customer. «In the last ten years our clients –Giacomello tells – have grown from eight hundred companies to about five thousands. We are living years of strong growth and we are very satisfied with being today an enterprise with its own identity, acknowledged both in Italy and abroad». The range of level gauges Giacomello can implement is highly articulated. Among the best-selling products in recent times, stand out LVC levels, visual levels with continuous output Ohm / 4-20mA, which have given unexpected satisfactions to the company. These products allow controlling the liquid level at any time, constantly, clearly and precisely. The used principle is the one of communicating vessels: the liquid coming from the tank to which the level indicator is applied, by means of hollow screws flows through the transparent pipe, revealing the precise point reached inside the tank. These solutions are used for chemical and hydraulic applications, which have scored surprising sales results indeed. «Among the other highly satisfactory product categories, – Daniele Giacomello adds –we can mention Atex-certified level gauges, which have disclosed us sectors where we were not present before. Today we can instead offer a high-quality product at competitive prices, also providing the level with such a modularity and a range of variables permitting us to manage the product according to customers’ requirements».

Highlights of LVC level gauge

The LVC visual level with continuous output Ohm / 4-20mA operates according to the principle of communicating vessels: the liquid coming from the tank to which the level indicator is applied, by means of hollow screws flows through the transparent pipe, revealing the precise point reached inside the tank. The visualization is made more efficacious by the introduction inside the transparent pipe of a float; this houses in its interior a magnet, whose field operates, without physical contact, small reeds placed inside a stainless steel tube applied to the level indicator.

The operation of such contacts allows the gradual switching on or switching off of heating elements, they too positioned inside the stainless steel tube (raster), generating a resistive signal that can be variously used (ex. 4-20 mA), proportional to the liquid level inside the tank. Various options are available and, among them, it is worth mentioning: axis distances from 200 to 3000 mm; different polymeric materials used for the transparent pipe, heads and O-rings. The product allows obtaining a constant continuous indication of the liquid level with high repeatability precision; a linear indication of the liquid level, irrespective of the tank shape and of the distance between level indicator and tank walls; a visual remote field indication of the level measurement; the activation, through sensors, of additional controls.

Evolution of the electromagnetic level

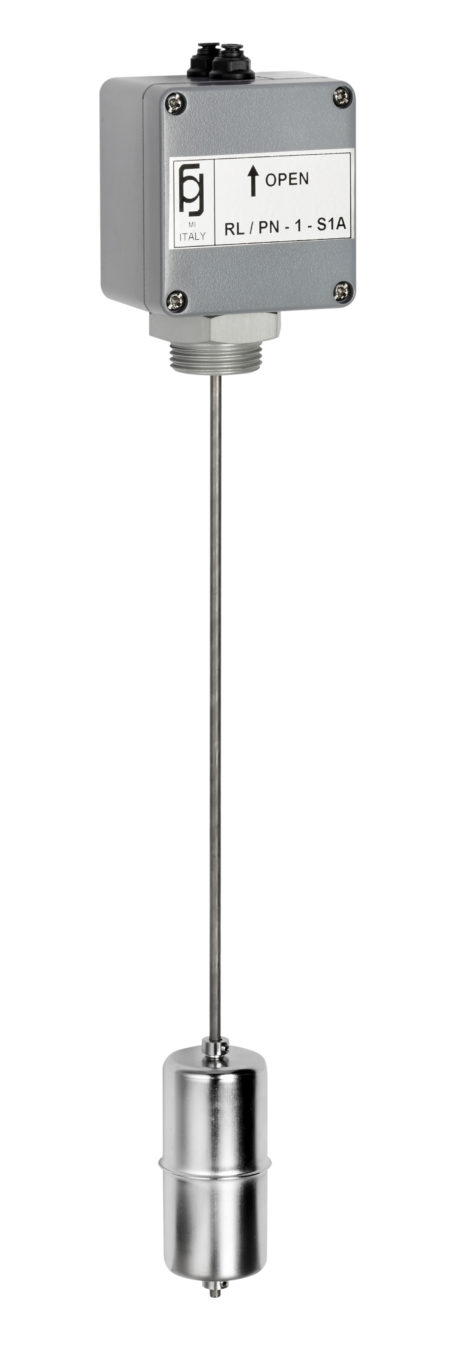

Among the products manufactured by F.lli Giacomello, one of the most representative is a typology of electromagnetic level patented by the company about twenty-five years ago, it replaced standard electromagnetic brass or stainless steel levels with one or more control points. Today, the product has evolved according to users’ new requirements but it remains one of the most representative implemented by the company. «This model of ours – states Daniele Giacomello – stands out from conventional ones because its electric and magnetic control parts are all positioned on the head, preventing these components from getting in touch with the liquid. The only parts that get in contact with the liquid are the float and the rod: this allows using the level with water, oil, diesel fuel and other substances, and in various applications. Compared to a traditional level, our product gives the advantage of not attracting metal particles or residues contained in the liquid, because the magnet is not plunged into it. Therefore, just to make an example, it can also be used in the refrigerating coolant of machine tools’ tanks».

Another noteworthy highlight of the electromagnetic level by F.lli Giacomello is the peculiar possibility of shortening it on the spot with a simple tube-cutter. Therefore, it is not necessary to order more levels of different sizes but it is possible to adapt the level from time to time, according to requirements. It can be also stocked up, ready for use in various applications as it can be modulated. «Since its first version –Daniele Giacomello explains – were born series of parallel levels, grouped under the RL range, which go from the standard model to the last one, RL-AT, which features a fully Aisi 316 structure, able to work up to 200°C of temperature, maintaining the peculiarities described: ideal in an environment where it is necessary that just stainless steel is in contact with liquids».

Levels conceived for hydraulics and Atex-certified

Hydraulic applications are currently more and more specific and peculiar. The liquids where levels are dipped are numerous and with the most various characteristics. Oils are of different type as well and can need levels with particular specifications. Therefore, the product customization is more and more complex but fundamental. «Aware of the manifold needs that our customers must face – Giacomello declares – we have enhanced our product customization skills at best. We can implement both the smallest level for small-size tanks and Aisi 316 or polypropylene products for applications at very high temperatures or with acids. Given the more and more frequent demand for certified products, precisely in the course of the current year F.lli Giacomello has focused on the implementation of a range of Atex-certified level gauges, to be used in all situations needing this certification, including heavy-duty ones. This level line is customized according to customers’ single needs, too, fixing on demand attachments, connections, length and intervention points.

«We collect all customer demands –Daniele Giacomello explains – and we try to satisfy all, undertaking a tailored design. Sometimes, the cues emerging in this phase give birth to new products or evolutions of already existing products. In that way, our research and development activity always remains dynamic and keeps pace with times. During 2019, we focused on certifications. We are accomplishing the ISO 9001. We then worked at forms to be delivered to customers with products: from use manuals to the various instructions for maintenance and installation and up to 3D designs that, to reduce the paper waste, we make available through QR code to be downloaded on-line when necessary».

When Atex certification is nedeed

CRXI level indicators (marked EX II 1/2 G Ex ia II C T5 Ga/Gb) are manufactured in conformity with Atex directive (2014/34/EU) to be used in the precise constant indication of the liquid level inside a generic tank, positioned in an environment containing, for a long period of time and with continuity, an explosive atmosphere, consisting of mixture with air or flammable substances under the form of gases, vapours or mists (zone 0 – ref. EN 60079-10). This type of indicators assures: the constant continuous indication of the level with high precision of repeatability; the linear level indication, irrespective of the tank shape and of the distance between level Indicator and tank walls; the remote indication of the measurement and possibility of additional control piloting. IEXD level gauges (marked EX II 1/2 G Ex d II C T6) are in their turn implemented in conformity with Atex directive (2014/34/EU), to be used in the control of different levels of a liquid inside a generic tank placed in an environment containing, for a long period of time and with continuity, an explosive atmosphere, consisting of mixture with air or flammable substances under the form of gases, vapours or mists.