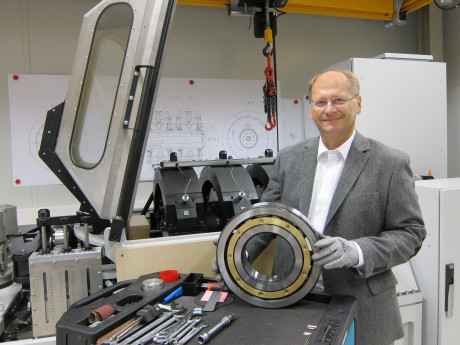

NKE Austria GmbH presents a new test rig for medium sized rolling bearings.

With the radial-axial test rig RAX380 for bearings with an outer diameter of up to 380 mm NKE is now capable of testing the running characteristics of bearings under varying test conditions and loads, speeds, lubrication conditions and temperatures. The new rig will be used to test standard bearings as well as custom and application-specific bearings.

At its headquarters in Steyr NKE operates its own test centre, which, in addition to the new RAX380 test rig for bearings of up to 380 mm, houses an RAX160 rig for testing bearings with up to 160 mm outer diameter. The test rigs yield valuable data about the tested bearings, such as their operating characteristics, wear and frictional behaviour and noise generation. In addition they allow to test the service life under the set operating conditions.

At its Steyr factory NKE manufactures components for bearings from 200 mm to 800 mm diameter. The quality and geometry of each component are tested both during and after production. Once assembled, bearing samples are subjected to function testing on the test rigs to determine their running characteristics and the interplay of their components. The running characteristics are mapped under defined load conditions with various radial and axial forces, speeds, lubricant temperatures and lubricant flow rates applied at each load level. Measured are the total frictional torque, vibration and the temperature rise on inner and outer race. “Although we calculate the running characteristics of every bearing design, testing is important to verify that our predictions are correct”, explains Thomas Langer, Development and Testing Manager at NKE. “This helps us optimize our simulation and design process and ensure the bearings’ trouble-free operation for our customers. Furthermore vibration cannot be calculated in advance; its measurement on the final product is therefore especially important.”

In addition, the test rig is used for durability testing under operating conditions: “These long-term tests can be run at constant load or with variable load levels”, explains Thomas Langer. “To obtain statistically significant results at least five test runs under the same conditions are required. Because each of these test runs can take more than a thousand hours, durability testing with only one test rig can never be a routine operation.”

For technical calculation of bearings all available resources are used, as Thomas Langer explains: “At NKE we use software guaranteeing that we adhere to the calculation methods defined in the applicable DIN ISO standards and by certification body Germanischer Lloyd. As member of German research association Forschungsvereinigung Antriebstechnik e.V., NKE will also have the opportunity to use Workbench. Applications like Mathcad, Minitab and FAMOS are available for test planning and measurement analysis.”

In addition to the new and existing test rigs for bearings with an outer diameter of up to 380 mm and 160 mm respectively, NKE’s test centre boasts a range of other equipment for materials, dimensional and function testing: spectrometers and hardness testers for material testing, height gauge, form and roughness gauges, a 3D CNC measuring machine, roundness and surface testers, a dimension measuring station for large bearings as well as vibration and noise testing equipment. “All NKE bearings undergo stringent, documented quality inspections at our headquarters in Steyr. Through the use of our test and measuring resources in combination with a rigorous quality policy we can guarantee that every single bearing we deliver meets the highest quality standards”, explains Harald Zerobin, Technical Managing Director at NKE. “To supplement our own inspection and test resources we also instruct external laboratories with regular and special inspection and testing. With the new test rig we can now run larger bearings under harsh operating conditions to determine their operating characteristics and demonstrate to our customers that they have made the right choice with bearings from NKE.”

NKE produces standard and special bearings for all industrial applications. Engineering, product development, production and final processing of components, modular assembly, quality assurance, logistics, sales and marketing – are centralised at NKE’s headquarters in Steyr, Austria. The factory in Steyr is certified to ISO 9001:2008, ISO 14001:2004 and OHSAS 18001. Its wide range of standard bearings is available from stock or at short production lead-times. NKE also provides tailored products and solutions. In addition to product development and application engineering NKE provides a full range of technical, consulting, documentation and training services. NKE’s products are distributed through 18 international representative offices and more than 240 distribution outlets in 60 countries.

Additional information about NKE test rig RAX380:

Technical specifications:

- Speed: up to 4500 r.p.m.

- Radial test load: up to 250 kN

- Axial test load: up to 75 kN

- Drive: asynchronous 35 kW servomotor

- Oil temperature: up to 120 °C

- Test mode: automatic load spectrum or individual stages

- Lubrication and cooling: oil or grease

- Lubricant flow rate: up to 12 l/min per test bearing (separate circuits)

Measured variables:

- Temperature:

- Torque

- Speed

- Radial and axial test load

- Cage speed, cage slippage, roller set slippage

- Oil pressure

- Oil quantities per bearing

- Vibration

- Inner race

- Outer race

- Lubricant infeed

- Lubricant discharge

- Oil sump

Possible test bearings:

- Cylindrical roller bearings, deep groove ball bearings, taper roller bearings, angular contact ball bearings, spherical roller bearings, etc.

- Single-row, double-row and paired bearings

- Grease or oil-lubricated bearings

- Inner diameter: from 50 to 240 mm

- Outside diameter: up to 380 mm

Possible tests:

- Running characteristics

- Service life.

We want to have a particular roller bearing (manufactured in China) , tested for its overall performance and durability standard.

the Bearing is under ref no. 382/385D – is is what we refer to as ” a double bearing” used mostly in disc harrow in agricultural machinery.

Please inform us if you can do the test and submit a report to us. as well as the costs of doing this job.

thank you

our address and contacts:

STACKFINE & CO. -COVMO UK

10 WOODLANDS ROAD

BUSHEY , HERTS. WD23 2LR , U.K.

TE.+44 1923 228536

MOBILE:+44 7931547865

Dear Sirs,

I thank you for appreciating the content of our digital magazine Power Transmission World.

For any request about NKE Bearings, you could directly contact the Austrian company to the following address:

NKE AUSTRIA GmbH

Im Stadtgut C4

4407 Steyr, Austria

Tel.: +43 7252 86667

Fax: +43 7252 86667 59

E-Mail: office@nke.at

Kind regards

Anna Bonanomi

Editor