Due to the forefront level of its vibration-damping and sealing systems, Pantecnica enters two new sectors. Let us discover what they are.

The Italian company Pantecnica, specialized in systems for the insulation and damping of shocks and vibrations and the fluid sealing, commonly called seals, has recently started developing solutions for two new sectors: the transport and the handling of works of art and medical devices. We met Davide Fatigati, General Manager of the company, who explained us the modalities and the reasons for this choice. Mr Fatigati first presented us his line of fluid sealing systems and vibration-damping systems: systems that range from rubber, rubber-metal to polyurethane, steel springs, steel cable and steel bearing, and can be used in whatever mechanics ambit or in several other fields, too. Concerning seals, Pantecnica can boast a long history, with a broad range that goes from standard seals to PTFE/Compounds systems, for instance, which are used in the ambit of big hydraulic cylinders. Fatigati talked with us about a very interesting application sector: «Our products are also suitable for the protection and the transport of works of art, with the same criteria applied in mechanics for the insulation of machines and plants».

A particular application: the works of art transport

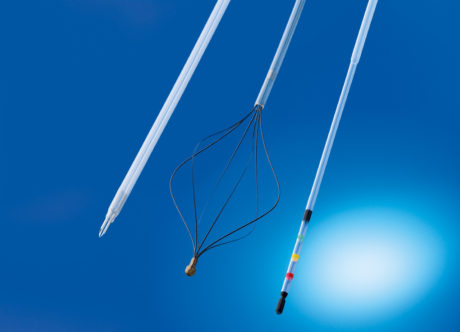

The transport of works of art requires some slings, strips of very resistant material that, however, must not get in touch with the masterpiece. Therefore, some strips made of polyurethane material are used for its protection. The same polyurethane strips can be used as both damping and high surface friction material. Some vibration-damping supports consisting of steel cables are used to protect the case content, too. In some cases, very precious objects must be protected against vibrations originally unforeseen. If a statue is exhibited in a city, for instance, where there are subway lines, the prolonged daily stress can damage the molecular structure of the granite. For Pantecnica it is a new sector, where it is lavishing many efforts. We asked Davide Fatigati what is the added value its company can offer: «Pantecnica collaborates with a specialized company that produces anti-seismic shakers, then we can test the materials we will use for these bases to assess their suitability for anti-seismic and vibration-damping applications. We started operating in this sector fortuitously, as a customer asked us for a transport solution. We anyway understood immediately that it is a receptive ambit, due to the richness of works of art, museums and exhibitions in our Country. They communicate us the size of the envelope, of the work of art and the type of stresses it will undergo and we study the most suitable vibration-damping device». Regarding this theme, Fatigati ended: «It is a new sector and it is very satisfactory to work in the culture area. In short, we can say our company offers technical-applicative consulting for the design, the development and the supply of systems for active and passive vibration insulation and shock damping, as well as fluid sealing systems and components with certification of materials and/or process systems».

The big development of medical sector

Pantecnica, thanks to the over thirty-year collaboration with the German represented company ElringKlinger-Engineered Plastics specialized in thermoplastic solutions and components, can offer highly innovative solutions, which today it is starting proposing to a very advanced sector like the medical one, then all that concerns equipment and machinery, for internal and external medicine uses, where seals or anyway components (for instance, pipes, membranes, bellows, bushes and so on) must be provided with a Compliance by the Food and Drug Administration (FDA) or by the United States Pharmacopiea (USP). Pantecnica has joined the Lombard Cluster Life Sciences and it is currently the only company that supplies this kind of technical components. Fatigati told us: «This is a sector with great potentials, too. Let us imagine to have a refrigerator containing drugs in a zone of high seismic risk. In case of earthquake, unless it is catastrophic, an operating room cannot stop and therefore the protection of the refrigerator and the drugs it contains is very important. Still speaking of this sector, let us consider seals: to make another example, let us imagine a robotic system for arthroscopy surgical interventions, maybe with remote control. The robot executes some controls but it needs high-technology seals in absence of friction. Fast and linear motions need PTFE seals.

Another technology, constant research

Still in this sector, the company headquartered at Rho (Milan, Italy) has developed other applications. Autoclaves are large cisterns inside of which some test tubes, for instance, are sterilized. In this case as well, there is the need of using seals or ball bearings that are made not only of stainless steel but also provided with cages of special thermoplastic material (ex. PEEK or Moldflon® ElringKlinger Engineered Plastics), rather than membranes or other materials getting in contact with fluids at very high temperatures. A company, then, that is developing in very different sectors one another, requiring a high technological level. Therefore, we asked Fatigati how much research and development matter in his company: «We invest hugely in it, with highly skilled experienced staff and with the target of being able to supply customers with tailored solutions. We do not address clients with some commodities but with technical solutions. If, speaking again of works of art, a customized protection is necessary, you cannot find it in internet… our choice is this». The medical sector, the General Manager of the company explained us, is very important. Italy is the second world exporter after Germany, with a turnover of almost 30 billion Euros. Milan is candidate to host the European Medicines Agency, which is currently located in London but, owing to Brexit, will have to find new headquarters. It is another sector Pantecnica is approaching with many energies, considering also Lombardy’s excellence in the medical and pharmaceutical ambit.

New strategic choices

Besides these new development sectors, it is worth highlighting the new strategic choices, which confirm the excellent quality of the company and of its products: «Already in 2008, we were satisfactorily admitted to both the Lombard Aerospace District and to Lombard Shipbuilding Production Chain, both acknowledged and supported by the Lombardy Region. For Pantecnica, Hydraulics and Pneumatics mean sealing systems, specialty of one of the two Divisions of our company (the other are vibration-damping systems), therefore we refer to Sealing Systems that address the entire industry world, not only the Mechanics one. Pantecnica, in fact, is present with its own engineering and its solutions in all industrial fields: from conventional Mechanics to Medical & Food, from Oil & Gas to Chemical, Marine, Military and Aeronautical sector, since it is EN 9120 Certified and member of the Lombardy Aerospace Cluster».

Pantecnica has operated in the Sealing Systems sector for 50 years, since in the Sixties it started supplying Rubber-Canvas solutions that were the only dominating material in this sector; afterwards, it introduced some new materials such as Polyurethanes and PTFE/Compound and Composite solutions that have started being released on the market since the Eighties. Pantecnica’s competence, engineering and design skills embrace all Fluid-dynamic applications, an actuator very often can require complex sealing solutions in its inside (concomitant linear and rotary or with different materials); this can presuppose the assembly of different products and materials that are not available by a single producer (manufacturers of rotary seals generally do not produce linear seals and vice versa, and likewise manufacturers of elastomeric solutions do not produce thermoplastic solutions and vice versa). Therefore, customers are not compelled to provision by several manufacturers to make their actuator work but they turn to Pantecnica, thus having the certainty of a solution that starts from an all-round vision and that considers the entire system in its whole. Essentially, the “specialty” is the salient characteristic of Pantecnica (Customized Technical Solutions).