Concerning the Italian manufacturing, FARO Industriale stands as excellence in production and revamping service of backing bearings for Sendzimir rolling steel mills

Due to their compact and massive structure, the Sendzimir cold rolling steel mills manage to obtain remarkable plate section reduction, operating at a high speed and heavy pressures. The processed product must match extremely tight thickness tolerances, flatness and surface finish.

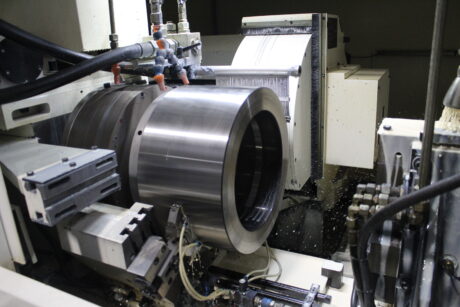

These kind of requirements can be fulfilled only if backing bearings rotate with extremely high accuracy. These multi-row cylindrical roller bearings are characterized by very thick-walled outer ring and different designs to satisfy various requirements. Their performance depends on the application in addition on extremely elevate working loads, in fact working as a wheel, their outer diameter is prone to abrasive wear, this reflects on the quality of the product during lamination. Hence the outer ring surface needs to be grinded periodically reaching uniform tolerances within the same set, restoring the original geometrical parameters.

Faro backing bearings quality is guaranteed by the use of high purity steel, being hardened accordingly to a new procedure, which permits to obtain optimal mechanical properties, as well as high precision machining and sophisticated measurement methods. These bearings are manufactured following restricted tolerances having more than P4 rotation accuracy. These features assure extremely high quality of laminated products in terms of surface finish and flatness.

An important service for the steel industry

Several decades of experience, acquired through collaboration with numerous clients, allows FARO to carry out the revamping of backing bearings through proven procedures.

This process allows to significantly extend the working life of each backing bearing, with a significant cost savings.

The revamping process brings back the bearing to “as good as new” status, with important costs savings consequence, allowing to keep elevate profitability production levels. An important point to pay attention to is that the revamping time is significantly lower than the production of new bearings.

Hence the bearings revamping is an important service for the steel industry, it bears not only costs savings and constant availability of pieces, but also decreases the risks of breakdowns and downtimes.

Six steps to revamping

The revamping procedure comprehends the following steps:

- Disassembling, washing and deep damage analysis (crack detection, hardness check, shape and dimensional control) evaluation of most convenient reconditioning process

- External grinding of entire bearing set of the rolling mill axle, in order to uniform the height of the section to the same values, through a minimal stock removal

- Damaged components replacement

- Washing and assembling

- New height section measurement with specific tool

- Preparation of a report documenting new obtained outer diameter and height section measurements after revamping is finished (all the remaining parameters are compliance with the standards for new bearings).