Rugged bearings are essential to ensure the reliable continuous operation of agricultural machinery in the field. NKE offers a range of special-purpose products with a particular focus on application-specific, ready-to-use bearing units: the so-called Agri Units.

Rugged, reliable bearings are essential to ensure the reliable continuous operation of agricultural machinery in the field. Adverse environmental conditions – mud, dust, impacts, stone chippings and water – take their toll on machines and their components. These must therefore be designed to withstand such operating conditions and be protected as effectively as possible from environmental influences. As agriculture is becoming more intensive, machines are also expected to offer ever increasing performance and endurance; the rolling bearings – which have many applications in agricultural machinery – must likewise keep pace with this development. Austrian manufacturer NKE offers a range of special-purpose products with a particular focus on application-specific, ready-to-use bearing units, the so-called Agri Units.

With Agri Units, NKE has come up with a generic term for bearing units designed for use in agricultural machines that require a rotating union between a disc-shaped tool and its mounting arm. Whereas producers of agricultural machinery previously often had to buy and assemble up to ten separate components, Agri Units represent a single part in the form of a fully assembled bearing unit. For the customer this means a cost saving, not least through a gain in efficiency, since purchasing, storage and spares inventories are limited to just one component and no prior assembly is needed. A high level of integration – i.e. the use of components that perform several functions – results in a high performance density.

A rugged bearing unit for use in disc harrows

The first step was to develop a rugged bearing unit for use in disc harrows with a disc diameter of up to 650 mm (Fig. 1).

The design, which is comparable with existing solutions of similar size, has a number of special features: an optimized internal geometry that maximizes load capacity and resistance to tilting moments; a high quality grease filling in a sufficiently high quantity for the operating conditions to ensure a long lubricant and therefore bearing life as well as good corrosion protection; a highly efficient combination of seals to prevent dirt ingress into the bearing (Fig. 2). In addition to the current standard version, NKE can adapt the unit’s external geometry to allow customers to integrate the unit into existing designs or tailor it to new applications.

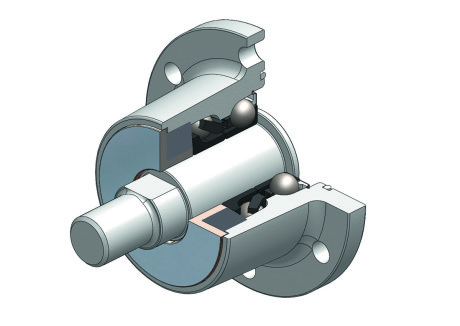

The second application in the field of Agri Units is for seeding discs and for liquid manure spreader discs, whose application is similar to the harrow discs, however of smaller size (see figure at the beginning). These bearing units aim to replace the conventional and often no longer satisfactory solutions consisting of deep-groove or double-row angular-contact ball bearings with an all-in-one compact bearing unit. In addition to optimizing the internal structure, lubrication, sealing and ease of handling of the bearing units for disc harrows, the designers focussed on minimizing the unit’s external dimensions.

Beyond the standard solution

Beside its new Agri Units product line, NKE offers standard and special bearings that also cover scenarios in agricultural technology in which bearing units cannot be used. This includes, for example, balers, power take-off (PTO) gearboxes and track systems. NKE also offers comprehensive technical support, including application consulting and the development of customer-specific solutions as well as commercial and logistic services, such as just-in-time (JIT) delivery.

NKE offers both standard and special bearings for all industrial applications. NKE’s core functions – engineering, product development, final processing of components, assembly, quality assurance, logistics, and sales and marketing – are centralised at its Steyr headquarters. In addition to product development and application engineering NKE provides a full range of technical services and training. NKE’s products are distributed through 15 international representative offices and more than 240 distribution outlets in over 60 countries.

Both standard and special bearings

NKE Austria GmbH is a bearing manufacturer with headquarters in Steyr, Austria. The company with about 140 employees was founded in 1996 by a group of senior staff members of former company Steyr Wälzlager. NKE offers both standard and special bearings for all industrial applications. Engineering, product development, production and final processing of components, assembly, quality assurance, logistics, and sales and marketing are centralised at its Steyr headquarters. The factory in Steyr is certified to ISO 9001:2008, ISO 14001:2004 and OHSAS 18001. Its wide range of standard bearings is available from stock or at short production lead-times. It also provides tailored products and solutions. In addition to product development and application engineering NKE provides a full range of technical services, consulting, documentation and training. NKE’s products are distributed through 15 international representative offices and more than 240 distribution outlets in over 60 countries. www.nke.at

SEE ALSO THE VIDEO: http://www.nke.at/de/downloads/video/