From the hard Research&Development work of TecnoCenter technicians, springs “Interpressa”, a linear system able to couple innovation and aesthetics wisely. The name itself derives from the assumption that the supplied axis is no more considered external to the machine, but integral part of the same and shares in the cycle time; Interpressa is in fact “inside presses”. An ideal solution for the industry of white goods.

Technology and aesthetics are two aspects of the white good industry that are exponentially evolving over the last few years, proving a stricter and stricter correlation. The trend of demanding for products that are well designed from the aesthetical point of view but also innovative and functional is involving both in the most demanding and the conservatory buyers.

Keeping in mind the last trends of the world market, for over forty years Tecno Center has been designing and implementing linear modules suitable for whatever customers’ requirements, creating competitive applications in every sector of automation and machine tools. Customization is the key factor in the management of the relationships with customers: the modules are studied and optimized upon demand, according to preventive feasibility studies, sizing of the transmission components and analysis of the process diagram, with complete supply of plates, accessories and fixing supports for the assembly of more axes, and to the possible customized machining on carriages and steel structural works.

Besides, key characteristic of the work at Tecno Center is to develop an intense collaboration relationship with customers, aiming at establishing a constructive dialogue and an exchange of information targeted to the creation of a shared design. To obtain the best from this collaboration and to create a relationship of mutual confidence with the customer, it is therefore essential to adapt ourselves easily and to exert a strong interpersonal flexibility.

The reduction of “downtimes” in productive cycles is the goal shared by all the producers of industrial automation. To satisfy this need, Tecno Center has developed a range of specific products for the white good industry, optimizing speeds and accelerations and notably reducing the cycle-time.

Interpressa Tecno Center was born

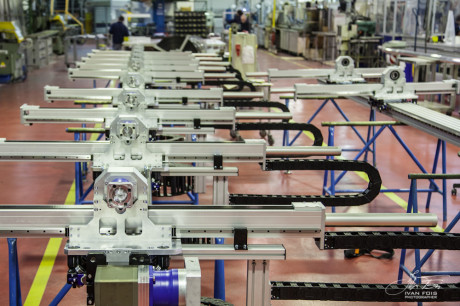

It was so born the “Interpressa Tecno Center” application, able to couple innovation and aesthetics wisely. The name itself derives from the presupposition that the supplied axis is no more considered external to the press but integral part of the same and it shares in the cycle time: Interpressa is in fact “inside presses”.

The systems are composed by double axes (Y, Z), and therefore while the vertical translation is performed by screw modules with pneumatic compensation cylinder, the horizontal one is entrusted to a belt with omega drive (the belt transmission is useful for maintaining fixed motors and consequently for eliminating the weight of the mobile motor on board of the carriages).

The quantity of modules depends on the axis length. Thanks to an attentive care in the reduction of the involved masses, it is also possible to reach accelerations exceeding 10 m/s2. The horizontal bar has optimized sizes to maintain a reduced axis thickness, permitting to limit the press sizes. The reduction of the masses at stake is also possible through the use of plastic materials , and the use of tie rods for the coupling of carriages performs also the function of cable passage.

A further innovation concerns the creation of the vertical ZMCHH module (section of the structural work 105×105 and 80×80), simple and compact, conceived paying particular attention to the energy saving. It is a single integrated whole that, thanks to the force of the pneumatic cylinder of load compensation, hidden inside the structural work and directly controlled by the drive head, allows lifting notable weights with notable vertical acceleration. The gearmotor input is possible on both sides and is equipped with high-performance guides with permanent lubrication.

Available also in the version without cylinder, it is suitable for all uses and, upon demand, a version with anti-corrosion treatment is supplied. Still upon specific customer demand, it is possible to add a tool attachment plate. To improve the aesthetics and to make the system free from encumbrances, the wiring for the equipment automation has been inserted inside the module.

A wide range of applications

Thanks to the flexibility, which has always characterized Tecno Center in design phase, its systems are successfully used in the production of household appliances and in packaging, in the automotive, machine tools and painting plants fields, in the glass, building, windows, wood and electronics industry. The qualitative and reliability performance characteristics of Tecno Center systems are useful also for the implementation of real special machine tools, for instance in the sectors of the drilling and milling of polyurethane resins, laminar wood, polystyrene and composite fibre panels.

In line with the change demanded by the market, today TecnoCenter feels the need of expanding towards new communication sectors, facing the challenges of digital media to grant a better online usability of resources through a renovated web site and completely new catalogues. It is working to update its communication style, proposing a new brand and a fresh and renewed product image.

Read more: www.tecno-center.it