High added value thanks to the research and development of new solutions, innovative applications designed and implemented entirely by the Servomech Group

Since the foundation in 1989, the Servomech Group has always been characterized by quality and innovation, with a made in Italy known internationally thanks to its specialization in the development and construction of advanced solutions for the linear motion. Electromechanical linear actuators, ball screw jacks, acme screw jacks, ball screws and nuts but also highly innovative and advanced mechatronic systems. All the products are designed and manufactured completely inside Servomech factory, using the most modern production technologies. Servomech internal production also grants to the market high level of quality, accuracy and flexibility, as well as a know-how consolidated by thirty years of experience. Thanks to these peculiar characteristics, that since its origins allow the company based in Anzola Emilia (Bologna – Italy) to stand out on the world scene, Servomech manages to constantly develop new products and serve the market also with customized solutions, specifically designed for its customers on the basis of specific requirements to satisfy the more diverse needs and applications. Among the Servomech products, the wide range of screw jacks with ball screw or acme screw are able to satisfy the most varied application needs.

Higher efficiency and performances

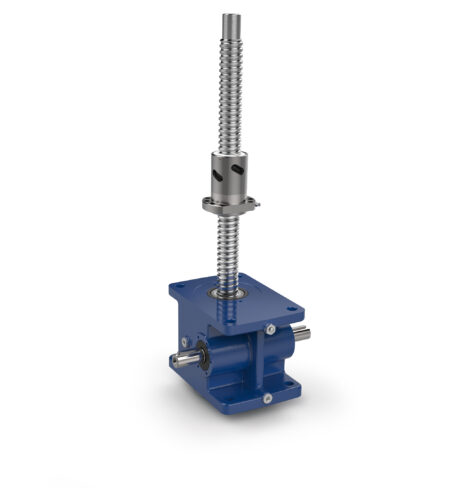

MA Series screw jacks with acme screw and MA BS Series screw jacks with ball screw are ideal for applications where high performance, high speed and eventual continuous duty cycle are required. They are characterized by the peculiar outer shape of the gearbox, for a better dissipation of heat and higher performances and duty cycle. It’s a monobloc housing, designed for a more compact and robust shape, able to carry heavy loads and ensure high precision level of machining. The lubrication with synthetic oil also improves the heat dissipation, together with an higher efficiency and performances and longer life. They are characterized by a low noise operation with input speeds up to 3000 rpm. Available on 8 different sizes with load capacity fron 5 kN to 350 kN, all the screw jacks are available with different input versions, flange and hollow shaft or bell housing and coupling for IEC motors or servomotors. According to the specific application requirements, customers can choose among ball screw drive with diameter from 16 mm to 120 mm or acme screw drive, 1 or more starts, with diameter from 18 mm to 120 mm. Both executions are available with travelling screw or travelling nut. Another not negligible aspect in the choice of the screw jack is the greater efficiency of the system with ball screw if compared to a traditional screw jack with acme screw. With same performance requirements in both systems (speed and load applied), ball screw jacks allow a 45 – 50% reduction of the installed motor power. Among the advanges using a ball screw jack execution, there is also no wear of nut and the absence of axial play, higher precision and repeatability in positioning as well as the technical calculation of the expected life of the product according to a given working cycle.

Servomech patented design

MA BS Series screw jacks are available in both models, with travelling ball screw or rotating ball screw and travelling nut. The choice of the model depends on the selected screw jack type or on the specific requirements of the application. When it is possible to choose between travelling screw and travelling nut model type, the Servomech patented design MA BS Mod. A travelling ball screw ensure higher level of performances if compared with similar products available on the market. Thanks to the internal production of all the components, including technology and proprietary know-how for the construction of ball screws and nuts according to its own specific design, Servomech created a new range of truly innovative ball screw jacks. Considering the several advantages obtained, Servomech has registered an industrial patent right for this specific screw jack model type.

Compared to the conventional type design, the patented Servomech solution provides a total integration of the various components of the gearbox and the ball screw, specifically designed and produced by Servomech for this series of products. The main advantage lies in the increase in the load capacity of the system thanks to the increased diameter of the ball screw. Servomech solution grants higher performances not only related to the load capacity but also referred to the efficiency of the system, duration and stiffness. Performances of the gearbox and of the ball screw are more balanced. The weight reduction, made by eliminating unnecessary components and material within this new design, contributes to the reduction of the overall inertia of the system. The immediate advanges that the market can take from this new solution are cost reduction thanks to efficient product and performance optimization, less energy consuption, higher load capacity for the same size, greater stiffness of the structure thanks to the native integration of the components. The screw jacks are available on 8 different sizes, with load capacity from 5 kN to 350 kN, ball screw diameter from 16 to 120 mm, input speed up to 3000 rpm, they can also be used with continuous duty cycle.