The Italian company Varvel promotes innovation, with the launch of the FRP680 gearbox for the poultry industry and a new modular square flange.

The Italian company Varvel, with over sixty years of experience in the design, production and sale of gearboxes, has a presence in over sixty countries around the world, and a strategic commitment to further internationalization.

This year Varvel launches the new FRP680 gearbox, developed for use in the farming industry and especially for the international poultry sector. The poultry sector is one of Varvel’s most important and dynamic customers and accounts for over 60,000 pieces a years.

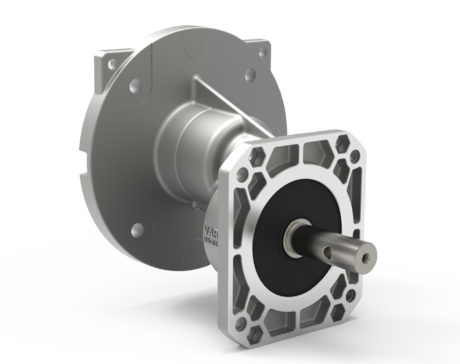

Coupled to a suitable motor, the new FRP680 gearbox is designed to drive the supply systems and screw conveyors that deliver animal feed. Years of experience in this sector have allowed Varvel to develop a gearbox capable of satisfying the key needs of today’s market: competitive price, versatility and customization. The FRP680 gearbox will be available in three different versions: an integrated version with a 160 mm input flange and a square output flange; a second integrated version with a 200 mm input flange and square output flange; a universal version for coupling to custom input and output flanges. The new gearbox is intended for use with motors 0.25 kW to 1.5 kW in power.

The decision to produce three different versions was made in response to the needs of the sector. The two integrated versions cover the market’s most common size and configuration needs and will make a major contribution to optimizing customers’ costs.

The universal version on the other hand offers maximum flexibility and customization and can be adapted to all necessary configurations, including those common in North America, whose huge poultry industry represents a new frontier with excellent growth prospects for the Varvel Group.

Modularity has always been the key guiding principle in Varvel’s development of new solutions, as it allows improvements to be introduced across the entire range of Varvel products and services.

The FRP680 boasts the same excellent characteristics as all Varvel gearboxes, and represents a major improvement in the company’s offering to the poultry industry. In developing this new gearbox, Varvel reviewed the entire product engineering process and introduced modifications to the gear meshing axes that have improved service factors by 10-15%. The FRP680 gearbox was also specially engineered to facilitate order management, making sales and after-sales services smoother and more open to customization. The supply chain for the FRP680 is 100% Italian, with all machining, gear profiling and functional testing performed within the Varvel Group itself. Components are optimized and the oil lubrication system features a universally renowned brand of top quality seals: small details but ones that help guarantee maximum efficiency and silent, leak-proof functioning.

The FRP680 gearbox is a brand new product that typifies the Varvel Group’s experience, attention to new markets, constant dynamism and commitment to supplying Italian excellence and precision engineering to the world.

Ever greater modularity

The new square flanges for servomotors and stepper motors will also give Varvel’s extensive offering greater modularity and will facilitate customization. This new range of square flange is designed to extend the scope for customization and make it easier than ever for customers to find the right solution to their needs.

IEC flanges conform to the same standards all over the world, but no unified design parameters exist for stepper motor and brushless servomotor flanges. As a result the diameter of couplings varies from one production area to another and there is no global compatibility. This situation obviously makes the market for square flanges extremely complex. Some manufacturers with specific needs demand custom designs to match the motors they use, while others set about adapting conventional flanges, not always with excellent results.

The Varvel Group has been applying standardized design solutions to its entire product range for many years. Now, Varvel is introducing a new range of square flanges for servomotors, capable of guaranteeing perfect coupling to all the popular Varvel gearboxes, and not just the RG Series of planetary gearboxes for which they were originally designed.The new catalogue offers manufacturers all over the world a range of square flanges perfectly suited to all Varvel gearbox sizes that can be coupled to common brushless servomotors and stepper motors. The new flanges will be available in sizes from 28 to 110 (corresponding to Varvel’s small and medium gearboxes) and made from anodized aluminium in conformity to the functional and stylistic standards of the Varvel product range.

This latest addition to the Varvel catalogue underscores the importance of modularity to Varvel. By permitting new coupling options, it will also improve the level of Varvel service. By simplifying configuration and coupling, the new flanges will improve competitiveness and allow manufacturers to offer packaged solutions based on perfectly integrated components, ready for use on end user machines.

The new flanges are further confirmation of the in-depth knowledge that only a company with decades of experience and a commitment to innovation can apply to the international market in general and to mechanical engineering sectors in particular.

Varvel USA LLC, the American subsidiary of Varvel S.p.A.

The Varvel Group was formed in Bologna, Italy, in 1955. Today, the group is known around the world as a representative of Italian excellence in precision mechanical engineering. The Varvel Group began internationalizing back in the 1960s, and since then has established an active community covering over 60 countries and all five continents.

Varvel has recently inaugurated a new subsidiary in the United States. Varvel USA LLC confirms the group’s interest in the flourishing North American market as well as its commitment to internationalization, a constant characteristic of its business strategies. Varvel inaugurated its first subsidiary outside Europe in 2011, when it formed the MGM-Varvel joint-venture in Chennai, India, a major step towards integrating and developing the group’s business in an exceptionally interesting market.

Varvel USA LLC is located in Peachtree Corners, Norcross, near Atlanta in Georgia, an extremely important logistic centre for the whole of North America. The 4500 square metre plant includes dedicated office space for the company’s administration, sales and management. The new Atlanta plant is linked to 27 warehouses and logistic centres around the country and maintains a generous stock of Varvel products. The new subsidiary will handle all after-sales activities for customers in the United States, from technical assistance to consulting on the design of custom solutions for specific applications. Varvel USA LLC can also count on an extensive sales and distribution network. To complement the service already offered to U.S. customers, Varvel has also signed a partnership agreement with one of the most innovative and dynamic electric motor distributors in the country. This new arrangement will allow Varvel to supply complete gearmotors with the best possible service backup.